Carbon-Capturing Benches (Japanese page)

One of the purposes of this research is to help improve tourism resources. With the cooperation of Kanazawa City, the bench was installed in Sotobori Park No. 2, located in the center of Kanazawa's tourism, with a design that takes into account the required safety performance and harmony with the surrounding environment.

There are Kanazawa Castle, Oyama-jinja Shrine, and the Nezumitamon Bridge that connects them, and you can feel the historical “Japanese”' atmosphere there, especially in Kanazawa. So this bench has a Yuzen nagashi motif to harmonize with the environment.

Installed benches

Installed benches 3D model of bench

3D model of benchAbout concrete materials

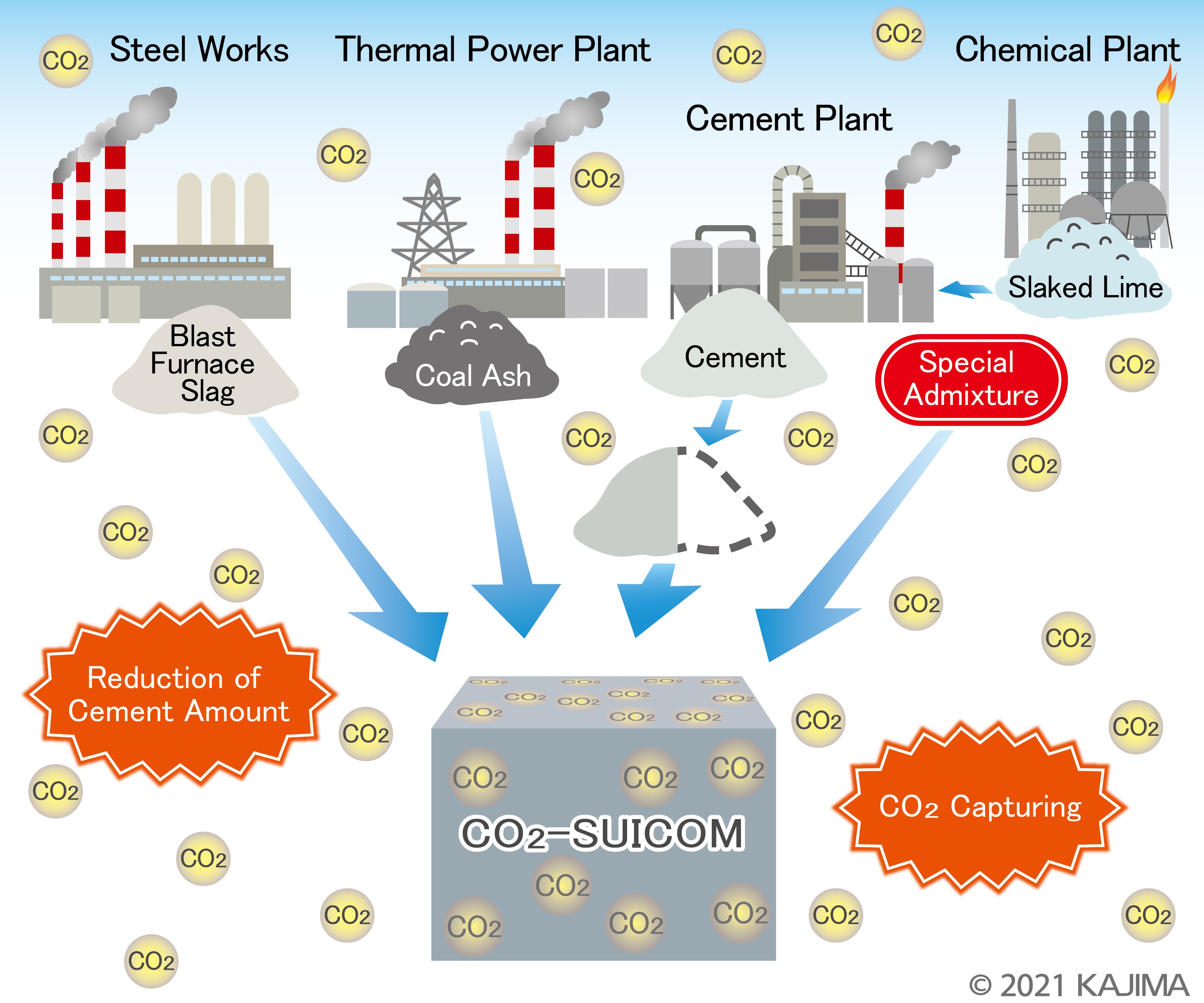

The material used for 3D printing is CO2-SUICOM* (CO2-Storage Utilization for Infrastructure by Concrete Materials), an environmentally conscious concrete developed by Kajima Corporation et.al. This forcefully absorbs and fixes large amounts of carbon dioxide during the manufacturing process. As a result, it is the only concrete in the world that can reduce total carbon dioxide emissions during concrete production to below zero.

About CO2-SUICOM

About CO2-SUICOM

KIT x KAJIMA 3D Printing Lab has a "carbonation curing tank", and parts made with 3DP forcibly absorb and fix carbon dioxide.

Carbonation curing tank

Carbonation curing tankThis bench is an innovative object that combines the most advanced "digital transformation" technology using 3DP and the most advanced "carbon negative" material using CO2-SUICOM.

* CO2-SUICOM®

CO2-Storage and Utilization for Infrastructure by Concrete Materials

CO2-SUICOM is a registered trademark of Chugoku Electric Power Co., Inc., Kajima Corporation, and Denka Corporation.

Background of installing a 3D printed bench

Advances in digital technology are playing an active role in various aspects of our society. One such technology, 3D printing (abbreviated as 3DP), is a manufacturing technology that stacks materials in layers based on digital data, making it possible to create three-dimensional and complex objects. This technology is also beginning to be applied in the construction field using mortar as a material. This degree of freedom is high, and it is possible to manufacture the product with less waste in terms of structure. Therefore, it is expected that the amount of wasteful materials will be decreased and the environmental impact will be reduced.

Kanazawa Institute of Technology and Kajima Corporation, which have been jointly conducting multiple research projects in the construction field, opened the "KIT x KAJIMA 3D Printing Lab" at Kanazawa Institute of Technology's Yatsukaho Research Campus in May 2023. A wide range of research and development will be carried out here, including design, structures, materials, construction, mechanical systems, robot control, surface treatment, processing, and development of needs.

3D Printer used in our laboratory

in processing

Kanazawa Urban Beauty Cultural Award

The "Yuzen Nagashi Bench," which was developed through industry-academia collaboration with Kajima Corporation and installed in Oyama-machi, Kanazawa City, was selected for the 47th Kanazawa Urban Beauty Culture Award. The award ceremony was held at 3:00 p.m. on February 19th at the Kanazawa College of Art Arena, and the certificate was presented to Director Miyazato by Vice Chairman Yonezawa Arihiro of the Kanazawa Urban Beauty Executive Committee.

(>> News Release(Japanese only))

About Kanazawa Urban Beauty Cultural Award

The aim of this awards is to raise public interest in the cityscape and contribute to further improving Kanazawa's urban landscape by honoring buildings and structures with excellent designs that blend in with the cityscape of Kanazawa. Citizens are invited to submit designs that they think are good, including buildings, townscapes, roads, bridges, street furniture, and signs, and the winners are selected based on the results of a document review and on-site inspection.Related information

Projection mapping for bench

As part of the interdisciplinary research that is a feature of KIT x KAJIMA 3D Printing Lab, we created projection mapping (media information) for benches (architecture/civil engineering/mechanical/robotics fields) created with a 3D Printer. Before installation at Sotobori Park, a projection experiment was conducted at Ogigaoka Campus, Kanazawa Institute of Technology. This trial led to expectations for the design results achieved through fusion with video content.

Contact

Kanazawa Institute of Technology

Research Support & Promotion Department (TEL 076-294-6740)